SẢN PHẨM

Năng lực R&D sản phẩm hàng đầu

Năng lực R&D sản phẩm hàng đầu

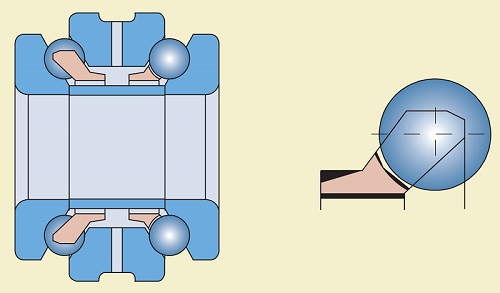

Double direction thrust angular contact ball bearing

Structure and characteristics

Double direction thrust angular contact ball bearing is a high-precision bearing specially designed for machine tool spindle, which can withstand axial load in two directions. Compared with the 511 series of thrust ball bearing, the ball assembled in the bearing has a small diameter, a large number of balls and a 60° contact angle. Therefore, the influence of centrifugal force is reduced, more resistant to high-speed rotation, large rigidity, size series 234400 and size series 234900 bearings, respectively, and cylindrical roller bearings NN3000K series and NNU4900K series of inner and outer diameter size is the same, withstand axial load.

Dimensions

The basic dimensions of two-way thrust angular contact ball bearing shall be implemented in accordance with the provisions of JB/6362.

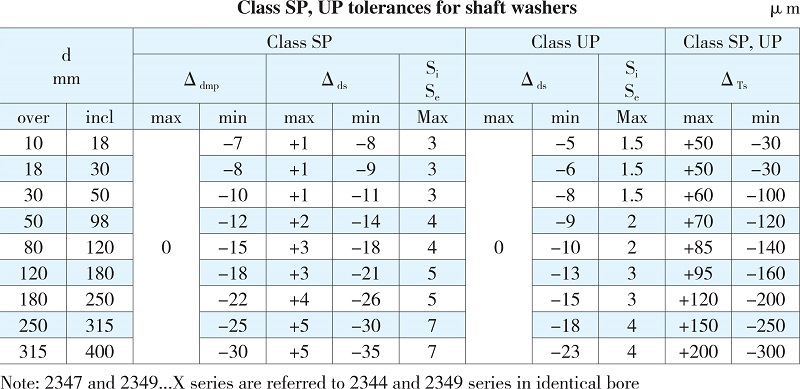

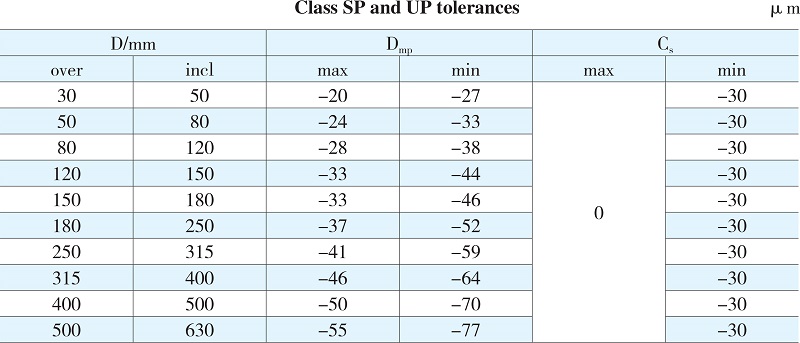

Tolerance grade

HRB Double direction thrust angular contact ball bearing are supplied to SP class tolerances, and upto UP class tolerances is available as well as request.

Cage

Machined brass cages are used. The cages with suffix BM1 are improved in structure design so that the allowable speeds are increased by 50% because of their reduced mass, more lubricating space, special brass and less frictional area.

Structural diameter of nylon 66 cages with bearing designation suffix TN.

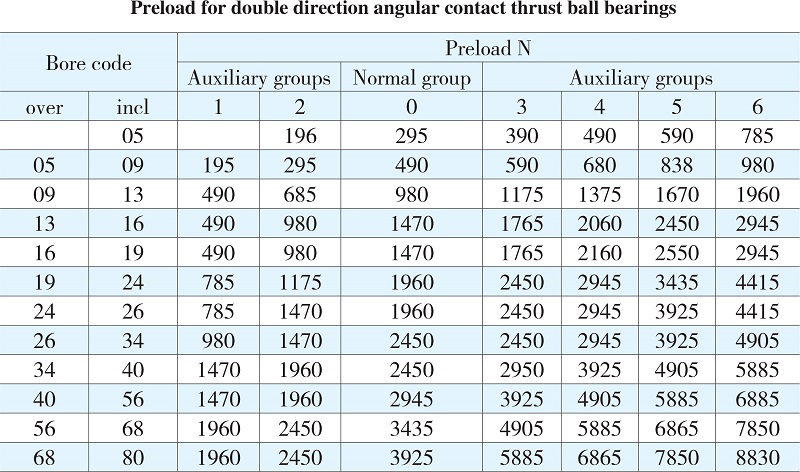

Preload

The preload of the Double direction thrust angular contact ball bearing is determined by the spacer diagram installed between the two shaft diagrams. The antenna of the Double direction thrust angular contact ball bearing is 60, so that the ball can be reliably guided when running at high speed. The use of thrust angular contact ball bearing can achieve significantly higher speed than the use of the corresponding thrust ball bearing.

Mounting dimensions

Bearing rings are only allowed to fit with shaft shoulders and support seat shoulders and cannot be stuck by the chamfer of shaft and housing. Therefore, the maximum chamfer radius of the matching piece ramax must be less than the thrust angular contact ball bearing corresponding chamfer of the minimum coordinate rsmin, the shoulder of the matching piece should be high enough to meet the maximum chamfer coordinate in the case can also have a sufficient supporting area, the table lists the chamfer radius ramax size and the diameter of the supporting shaft shoulder recommended to cooperate with the shaft diagram.

Recommendable fits